In today’s fast-paced construction world, speed, efficiency, and durability are no longer optional—they’re expected. Among the most commonly used materials for industrial and commercial roofing or enclosures are Tin Sheds and PUF Panels. Each serves a different purpose and comes with its own set of benefits. Whether you’re building a warehouse, site office, cold storage, or temporary shelter, knowing the difference between the two can help you make the right installation choice. In this blog, we’ll break down the pros, use-cases, and differences between Tin Shed and PUF Panel installations — and how Fabribbon ensures both are installed professionally, with zero hassle.

What Are Tin Sheds and PUF Panels?

Tin Sheds are typically made from galvanized iron (GI) or aluminum sheets. They are widely used for roofing, sheds, farm structures, parking covers, and temporary site enclosures. Lightweight and easy to install, tin sheds are the go-to choice for large-span, low-cost roofing.

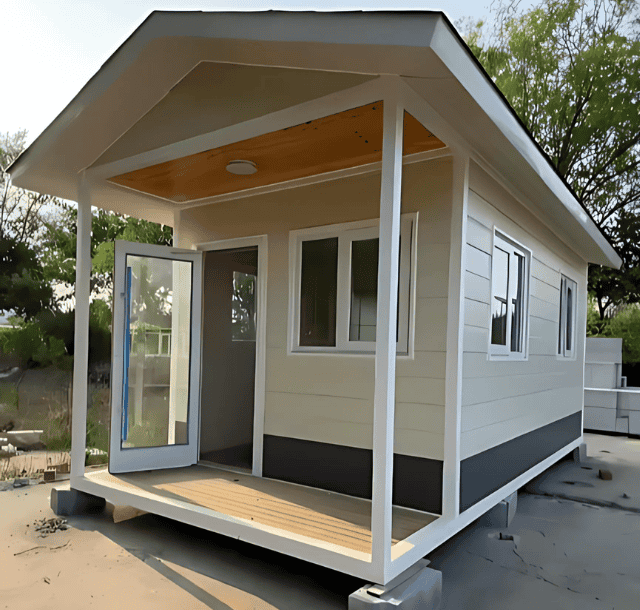

PUF Panels (Polyurethane Foam Panels) are insulated sandwich panels made from a rigid foam core between two metal sheets. These panels provide excellent thermal insulation and are ideal for rooms that need temperature control — like cold storage, portable cabins, site offices, and prefabricated buildings.

1. Installation Speed and Efficiency

One of the biggest concerns for any construction project is how quickly the structure can be installed. Both Tin Sheds and PUF Panels are prefabricated, making them easy to transport and quick to install.

Tin Shed Installation:

- Faster to erect, especially for simple roof sheds.

- Ideal for urgent project needs or temporary shelter.

- Can cover large open areas quickly with fewer materials.

PUF Panel Installation:

- Slightly more time-consuming due to joint sealing, alignment, and insulation handling.

- Requires skilled labour for airtight finishing and wall-floor sealing.

- Offers a complete room enclosure — not just roofing.

Fabribbon ensures both are handled efficiently with skilled teams — from truss fitting to final anchoring.

2. Cost Comparison: Budget vs. Function

Tin Sheds are generally more cost-effective for large-area roofing. If you’re covering a godown, parking, or machinery, tin is the budget-friendly choice.

PUF Panels, on the other hand, cost more due to their insulation properties and finishing requirements. But in return, they save energy costs and ensure climate control.

✅ Choose Tin Sheds for cost-efficient shade structures

✅ Choose PUF Panels when you need insulation and enclosed rooms

3. Insulation and Thermal Performance

Thermal control is one of the biggest differences between the two.

- Tin Sheds: Conduct heat easily; interiors become hot in summer unless additional insulation (like fiberglass or reflective sheets) is added.

- PUF Panels: Built-in insulation with 40–60mm foam core that keeps interiors cool in summer and warm in winter. Ideal for temperature-sensitive storage or working conditions.

If your structure demands human occupancy, cold storage, or perishable goods, PUF Panels win hands down.

4. Durability & Strength

Both Tin and PUF materials are durable when installed correctly — but there are key differences:

- Tin Sheds can last over 10–15 years with basic maintenance, but are more prone to dents, rust, and damage if exposed directly to harsh weather.

- PUF Panels are rust-resistant, waterproof, and maintain their insulation value over time. They also offer better soundproofing and structural strength.

At Fabribbon, we use quality GI/PPGI sheets, precise fabrication, and trained installers to ensure longevity for both.

5. Use-Cases: Which One Works Where?

| Scenario | Best Material | Why |

| Farm shade or tractor shed | Tin Shed | Quick roof solution, low cost |

| Cold storage room | PUF Panel | Thermal insulation, tight enclosure |

| Factory machinery cover | Tin Shed | Large open coverage, economical |

| Portable site office | PUF Panel | Ready-to-move cabin with comfort |

| Rooftop storage room | PUF Panel | Lightweight, thermally insulated |

| Parking Shed | Tin Shed | Simple shade, easy drainage |

| Security cabin / toll booth | PUF Panel | Compact, durable, insulated |

6. Maintenance and Upkeep

- Tin Sheds require occasional painting, rust protection, and fastener checks.

- PUF Panels require minimal maintenance, with proper sealing lasting years.

Fabribbon installers use weather-resistant screws, frame coatings, and alignment tools to minimize future maintenance.

7. Long-Term ROI and Energy Savings

PUF Panels may cost more upfront but save money long-term by reducing energy bills (AC, heaters) and enhancing work comfort.

Tin Sheds serve as reliable shade and cover but don’t offer insulation — so may need additional layers later.

Conclusion

Both Tin Sheds and PUF Panels have unique roles in the prefab construction ecosystem. While tin sheds win on speed and budget, PUF panels lead in insulation, comfort, and long-term efficiency. The key lies in choosing the right material for your purpose — and making sure the installation is done right.

At Fabribbon, we specialize in both Tin Shed and PUF Panel installations — delivering professional service, skilled labour, and fast execution across cities. Whether it’s a small rooftop cabin or a 10,000 sq. ft. warehouse, we make prefab installation easy, clean, and reliable.

Need a quote or site visit?

👉 Call or WhatsApp: +91 7448008760

👉 Visit: fabribbon.com

Let Fabribbon bring expert installation right to your site — zero delays, zero stress.